Hydraulic Freight Lift vs Traction Elevator: Key Differences, Applications, and Buying Guide

Introduction

When choosing a freight lifting solution for factories, warehouses, workshops, or logistics centers, one of the most common questions buyers ask is: Should I choose a hydraulic freight lift or a traction elevator? Although both systems are designed to move goods vertically, their working principles, costs, installation requirements, and ideal applications are very different.

This article provides a clear, practical, and SEO‑friendly comparison of hydraulic freight lifts and traction elevators, helping buyers, distributors, and project managers make the right decision based on real operating conditions rather than marketing claims.

What Is a Hydraulic Freight Lift?

A hydraulic freight lift uses a hydraulic pump station to push oil into a cylinder, lifting the platform or cabin upward. When descending, the oil flows back to the tank in a controlled manner. The system can be direct‑acting or combined with chains and wire ropes, depending on design and load capacity.

Key Characteristics of Hydraulic Freight Lifts

- Strong load capacity, commonly 1–30 tons

- Low lifting speed, usually 0.05–0.2 m/s

- Suitable for low‑rise buildings (generally up to 12–15 meters)

- Simple mechanical structure

- High tolerance for uneven loading

Hydraulic freight lifts are widely used in factories, warehouses, construction material plants, maintenance workshops, and industrial facilities, especially where heavy or bulky goods are transported using pallets or forklifts.

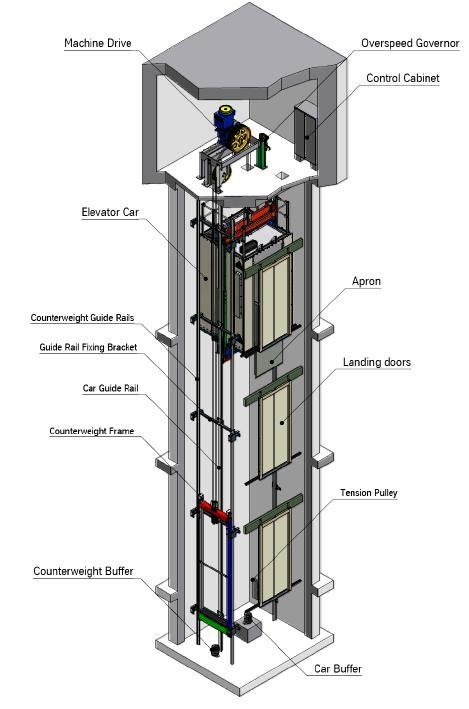

What Is a Traction Elevator?

A traction elevator operates using an electric motor, traction sheave, steel wire ropes, and a counterweight. The motor drives the sheave, and the friction between the ropes and sheave moves the cabin up or down while balancing weight with the counterweight.

Key Characteristics of Traction Elevators

- Higher operating speed (0.5 m/s and above)

- Energy‑efficient during continuous operation

- Suitable for mid‑rise and high‑rise buildings

- Complex mechanical and electrical systems

- Strict requirements for shaft accuracy and maintenance

Traction elevators are commonly used in commercial buildings, standardized logistics centers, and multi‑story automated warehouses where speed and efficiency are priorities.

Hydraulic Freight Lift vs Traction Elevator: Core Differences

1. Working Principle

- Hydraulic freight lift: Push‑type lifting using hydraulic oil pressure

- Traction elevator: Pull‑type lifting using motor‑driven steel ropes and counterweight

This fundamental difference affects almost every other aspect, from installation to maintenance.

2. Load Capacity and Durability

Hydraulic freight lifts are designed for heavy‑duty freight handling. They can easily handle concentrated loads, uneven pallets, and frequent impacts from forklifts. Traction elevators, while capable of carrying goods, are more sensitive to load balance and shock.

For harsh industrial environments, hydraulic freight lifts usually provide better durability and reliability.

3. Installation Requirements

Hydraulic freight lifts are extremely flexible in installation:

- Can be installed with shallow or no pit

- No strict overhead height requirements

- Steel structure shafts are acceptable

- Ideal for renovation or existing buildings

Traction elevators require:

- Precisely constructed shafts

- Fixed pit depth and overhead clearance

- Professional elevator installation teams

This makes hydraulic freight lifts more suitable for old factories and developing markets.

4. Speed and Efficiency

Traction elevators are clearly superior in speed, making them ideal for high‑frequency vertical transport. Hydraulic freight lifts operate more slowly, but this is rarely a disadvantage in freight applications where safety and load stability matter more than speed.

5. Safety Concept

Hydraulic freight lifts rely on passive safety:

- Hydraulic lock valves prevent sudden drops

- Controlled descent during power failure

- Simple, predictable failure behavior

Traction elevators rely on system‑level safety:

- Multiple sensors and electrical protections

- Emergency braking systems

- High dependence on regular maintenance

In low‑rise freight scenarios, hydraulic freight lifts are often considered safer due to their simplicity.

6. Cost and Maintenance

- Hydraulic freight lift: Lower initial cost, simple maintenance, lower skill requirement

- Traction elevator: Higher purchase and installation cost, professional maintenance required

For many overseas buyers, total cost of ownership strongly favors hydraulic freight lifts.

Which One Should You Choose?

Choose a hydraulic freight lift if:

- You need to transport heavy goods or pallets

- The building height is low to medium

- Budget control is important

- Installation conditions are limited

- Local maintenance resources are basic

Choose a traction elevator if:

- The building is mid‑rise or high‑rise

- High speed and efficiency are required

- Loads are standardized and well controlled

- Professional maintenance is readily available

Conclusion

Hydraulic freight lifts and traction elevators are not competitors in the same sense—they are solutions optimized for different realities. Hydraulic freight lifts focus on strength, simplicity, and adaptability, while traction elevators emphasize speed, efficiency, and standardized operation.

Understanding these differences helps buyers avoid over‑engineering or under‑specifying their lifting solution. For most industrial freight applications, especially in cost‑sensitive or developing markets, hydraulic freight lifts remain the most practical and reliable choice.